Large Fabrications and large castings often require machining of large bores. The large machining contract supplier must have machines, tools, gages, processes and data collection systems in place to machine close tolerance large bores to the customer’s requirement.

Large bores can be machined on a horizontal boring mill or on a vertical gantry mill. There is often a relatively large amount of stock removal on a large bore in a large casting or large fabrication. Compared to the location and diameter tolerances on the final machining operation the casting and fabrication location tolerances are large. A rough machining operation to reduce the amount of stock left for finish machining is required. Any operations that are required around the bore like face milling, drilling and tapping are performed before the finish bore operation. Any distortion of the part that will occur from these operations will occur before the finish bore is machined. These practices are common for all large machining suppliers. Picture # 1 shows rough machining of a 19.5 inch diameter bore with a milling cutter on a large vertical gantry machine. Picture # 2 shows drilling of bolt holes around the bore.

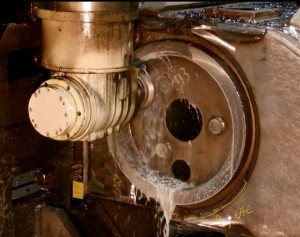

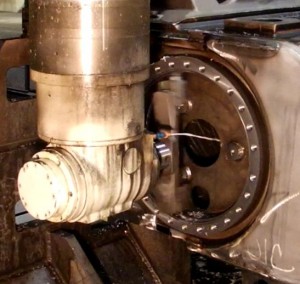

Large machining suppliers will standardize on one or more tools for large boring operations. Big Kaiser is one supplier of large boring tools. These tools are modular and can be setup for a range of bore sizes. Increments of adjustment on the boring heads are typically 0.0005 inches. Fine adjustment of the boring tool is possible even for large bore sizes. Picture # 3 shows the boring tool, picture # 4 is the boring head. Picture # 5 shows the boring operation in process on the large vertical gantry machine.

Large bores must be measured accurately to verify the bore diameter meets the customer requirement. Lot sizes are often small (frequently one) in the large machining industry. Gages must be flexible and accurate. ID mics (Internal Diameter Micrometers) are often used to measure bore diameters. These gages are calibrated to a standard in the plant which is traceable to a national or international standard. The ID mic in use to measure the bore is shown in picture # 6. Picture # 7 is a closer shot of the ID mic. The calibration sticker which shows the due date for the next calibration of the ID mic is shown in picture # 8. The calibration due date is 03/06/15; the date of the picture is 02/09/15.

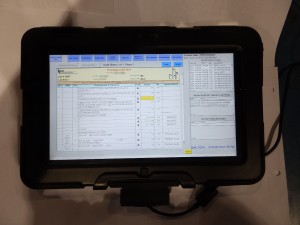

The traceability of the measurement of each large bore diameter to a specific part is desirable and may be required by the customer. The data collection of the bore diameter by the machinist using a gage traceable to a national or international standard, and retention of that data traceable to a specific part serial number by the large machining supplier is a valuable service. Electronic data collection on the shop floor is a cost effective method to capture gage readings and link the data to the specific part. Picture # 9 shows a table computer used on the shop floor by the machinist to record bore diameters and other measurements. This data becomes part of the supplier’s quality information that is tied to the ERP (Enterprise Resource Planning) system. This data can be retrieved in the future based on the serial number of the part that was machined. There may be a need for this information after the part has been in the field for years. A good measurement, data collection, and storage system at the large machining supplier is valuable to the supplier, the customer, and the end user of the product. A video of this boring operation is available below.