Leadership Through Quality

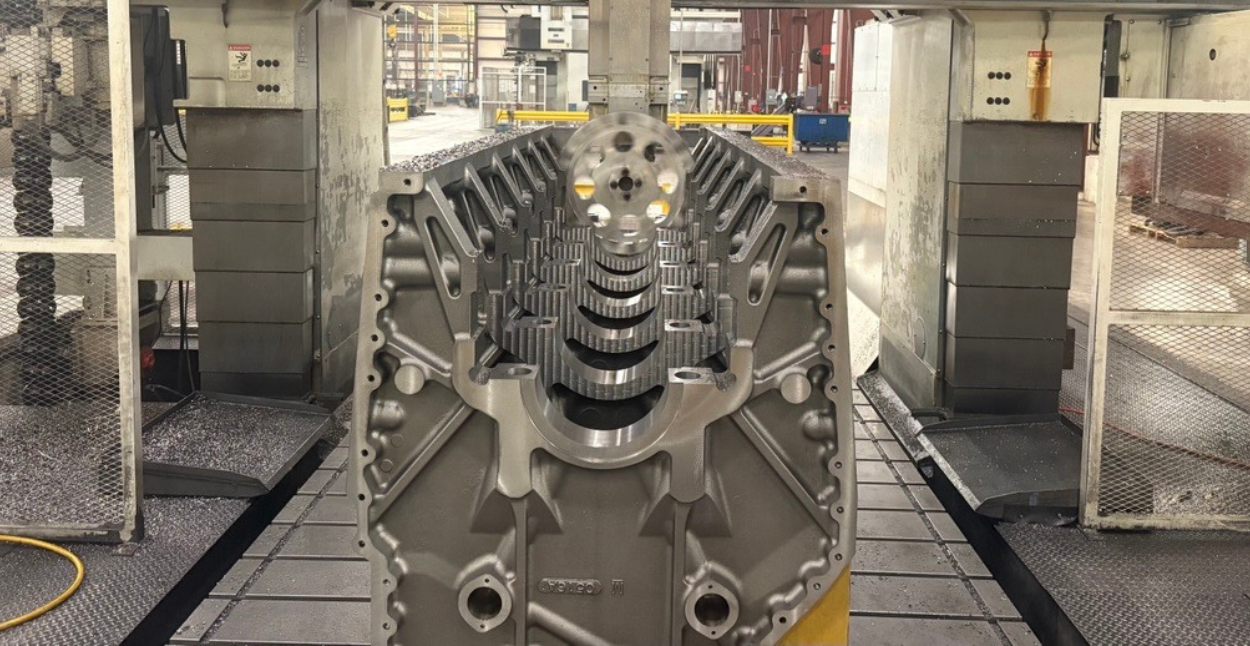

Machining

With decades of precision machining expertise, K&M consistently delivers high-volume, tight-tolerance components that meet or exceed stringent quality assurance standards. Our manufacturing process is optimized for repeatability, accuracy, and long-term reliability at scale.

Fabrication

K&M’s fabrication shop offers multiple robotic welding cells complemented by certified welding specialists trained in a variety of techniques. Large fabrications are our specialty. AWS Qualified Welders and access to Certified Welding Inspectors and Certified NDT services.

Burning

K&M’s in-house burn shop offers a multiple head plasma and a laser burning table that can handle a broad range of plate sizes and thicknesses.

Inspection

K&M’s inspection capabilities include a large CMM and a Keyence portable CMM. Laser tracker measurement services are also available.

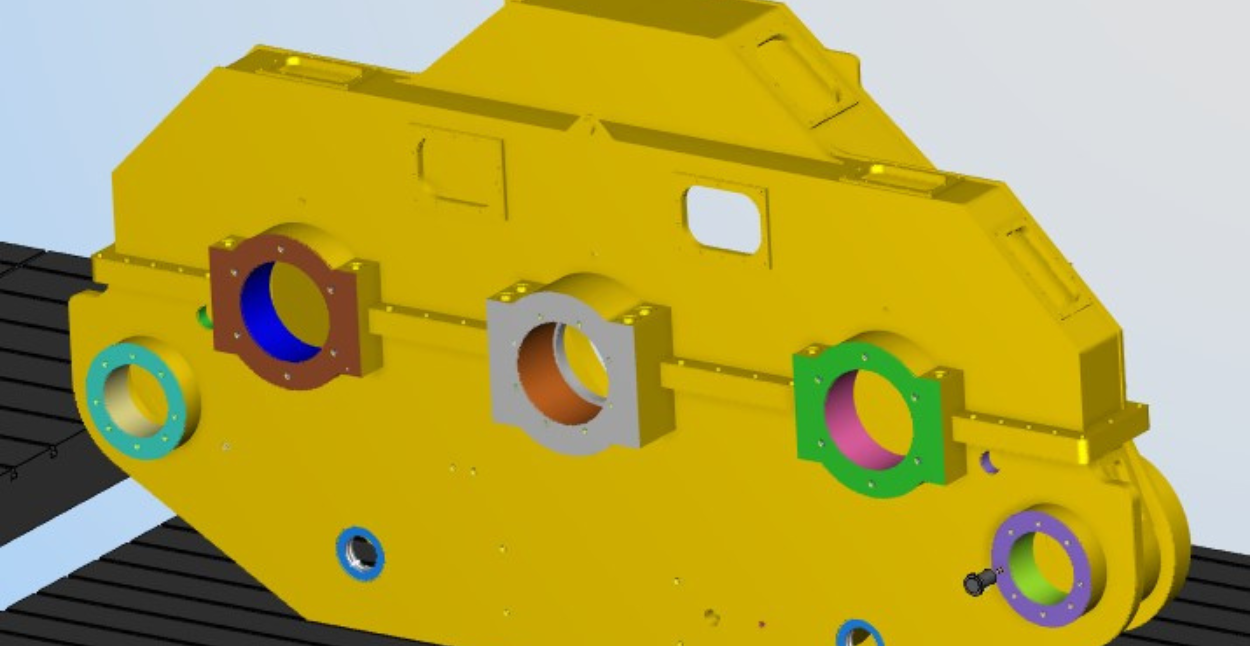

Engineering

K&M’s engineering provides fast quote turnaround, design for manufacturability evaluation, tool design, project management, control plans, PFMEA, and fixture designs/build. K&M engineering is experienced in the latest tooling, welding, and machining processes. This experience is applied to our customers’ products to provide a cost effective and high quality manufacturing process.

Assembly

K&M offers cost-effective electrical, hydraulic, and mechanical assembly services.

Sculpture Fabrication

K&M’s nationally recognized Sculpture Fabrication Division provides a useful resource for artists that work with large scale metal designs.

Machine Equipment

| 11 Horizontal Boring Mills Ranging From: | |||

|---|---|---|---|

| Pallet Size | 1250×1250 | To | 3000×3500 |

| X travel | 1600 | To | 20000 |

| Y travel | 1500 | To | 5000 |

| 3 Horizontal Machining Centers Ranging From: | |||

|---|---|---|---|

| Pallet Size | 1600×1600 | To | 2000×2500 |

| X travel | 3000 | To | 4000 |

| Y travel | 2500 | To | 3000 |

| 10 Vertical Machining Centers Ranging From: | |||

|---|---|---|---|

| Pallet Size | 2000×5000 | To | 3500×10000 |

| X travel | 5200 | To | 11000 |

| Y travel | 2900 | To | 4900 |

| 1 Lathe – Vertical: | |||

|---|---|---|---|

| Pallet Size | 1500D-1800H | ||

| X travel | 1200 | ||

| Y travel | 900 | ||

Fab Equipment

| Esab MRK 300 Arc Center | Esab CaB 300 |

|---|---|

| 4m Column Travel, 4m Boom Travel | 3m Column Travel, 3m Boom Travel |

| 50′ Rail Carriage plus Joint Tracking & Positioning | 50′ Rail Carriage plus Joint Tracking & Positioning |

| 1250 Amp Welding Head – Sub-Arc Single or Dual Wire Capability | 1250 Amp Welding Head – Sub-Arc Single or Dual Wire Capability |

| 150 Amp Plasma Gouging Head, Esab Pema 7000 Positioner | 150 Amp Plasma Gouging Head, Esab Pema 700 Positioner |

| 3 Axis Lifting, Rotating, Tilting – 15,000# Max. Load | 3 Axis Lifting, Rotating, Tilting – 15,000# Max. Load |

Burn Equipment

| ESAB Thermal Machining Center | Cincinnati 707 Laser Cutting Machine | 500T Accurpress Brake Press |

|---|---|---|

| Waterbed 20′ x 56′ | CNC Controlled | Model 750012 |

| Plasma Rotary Bevel Head – Chamfering up to 1½” Thick | 4000 Watt, 8′ x 20′ Table – Cutting 1″ and Below | with ETS3000 Control |

| 4 Oxy Fuel Torches – Cutting 1½” and Above | ||

| CNC Controlled |